|

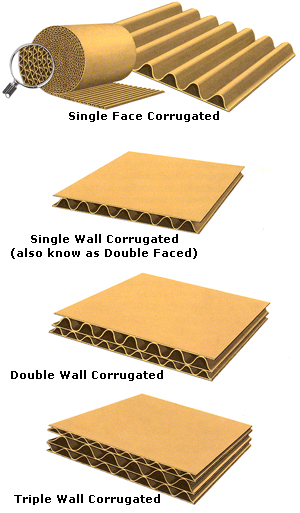

Corrugated Fibre Board Sheets

Solid fibre sheets are constructed by gluing two or more flat

plies of paperboard together. Usually, the outer ply is liner board, and the

other piles are corrugating material for filler paper boards. The inner ply also

may be liner board.

Modified corrugators can be used to make solid fibreboard.

Usually, however, it is made on less complex machines called pasters, which

apply adhesive to the entire surface of each layer.

The board can be scored in the machine direction, cut to

dies tired widths and cut off to desired lengths, just as corrugated board is on

a corrugator.

My using layers with different basis weights, the thickness of

the finished material can be changed. Solid fibreboard is usually produced in

thickness ranging from 0.045 inches (45 points, or about 3/64ths of an inch) to

0.135 inches (135 points, or a little more than 1/8 inch. For special

applications, it can be made as much as ¼ inch thick.

| Linerboard Performance Standards |

Max Wt. Box/Contents

(lbs.) |

Min. Burst Test Single/Double Wall

(lbs. per sq. in.)* |

Min. Edge Crush Test (ECT)

(lbs. per in. width) |

| Single Wall Corrugated Boxes |

| 20 |

125 |

23 |

| 35 |

150 |

26 |

| 50 |

175 |

29 |

| 65 |

200 |

32 |

| 80 |

250 |

40 |

| 95 |

275 |

44 |

| 120 |

350 |

55 |

| Double Wall Corrugated Boxes |

| 80 |

200 |

42 |

| 100 |

275 |

48 |

| 120 |

350 |

51 |

| 140 |

400 |

61 |

| 160 |

500 |

71 |

| 180 |

600 |

82 |

| Triple Wall Corrugated Boxes |

| 240 |

700 |

67 |

| 260 |

900 |

80 |

| 280 |

1100 |

90 |

| 300 |

1300 |

112 |

* Minimum puncture test, Triple Wall board (in. oz. per in. of tear)

NOTE: The above material references and

images are used courtesy of the Fibre Box Handbook © 1919-2007 Fibre Box

Association

|